Diferenças entre edições de "Laser Safety Manual"

| (Há 26 edições intermédias do mesmo utilizador que não estão a ser apresentadas) | |||

| Linha 1: | Linha 1: | ||

| + | '''Latest revision: March 2025''' | ||

| + | |||

Laboratory workers must be aware of its potential hazards, which can affect people, equipment, and the environment. In particular, safety is of paramount importance in a high-power laser laboratory. A safety manual is a foundational document that ensures the well-being of everyone working within the laboratory environment. | Laboratory workers must be aware of its potential hazards, which can affect people, equipment, and the environment. In particular, safety is of paramount importance in a high-power laser laboratory. A safety manual is a foundational document that ensures the well-being of everyone working within the laboratory environment. | ||

| Linha 411: | Linha 413: | ||

* Insulation and barriers: High-voltage cables and equipment should be properly insulated and enclosed to prevent accidental contact. Ensure barriers or physical guards are in place where necessary. | * Insulation and barriers: High-voltage cables and equipment should be properly insulated and enclosed to prevent accidental contact. Ensure barriers or physical guards are in place where necessary. | ||

* Avoid placing electrical cables in high-traffic areas to reduce the risk of tripping and damage. If unavoidable, use rubber cable covers (see figure) to protect both cables and people. | * Avoid placing electrical cables in high-traffic areas to reduce the risk of tripping and damage. If unavoidable, use rubber cable covers (see figure) to protect both cables and people. | ||

| − | * Neither cables nor electrical equipment should | + | * Neither cables nor electrical equipment should be laid in areas prone to water accumulation (e.g., near the ATU or the water basin) to avoid electrical shock hazards. |

* Whenever possible, run cables along walls or optical tables using cable trays or conduits. | * Whenever possible, run cables along walls or optical tables using cable trays or conduits. | ||

* Keep cables away from sharp objects or edges that could cause damage or fraying of the insulation. | * Keep cables away from sharp objects or edges that could cause damage or fraying of the insulation. | ||

| Linha 528: | Linha 530: | ||

{| class="wikitable" | {| class="wikitable" | ||

| + | ! Laser class !! Description !! Safety measures | ||

| + | |- | ||

|style="width: 10%"| '''Class 1''' || These lasers are considered safe under all conditions of normal use. The output power is low enough that it poses no hazard, even with prolonged exposure. Example: laser printers. | |style="width: 10%"| '''Class 1''' || These lasers are considered safe under all conditions of normal use. The output power is low enough that it poses no hazard, even with prolonged exposure. Example: laser printers. | ||

| − | + | || No specific safety precautions are required, but it is important to ensure the laser is used as intended and remains properly enclosed. | |

|- | |- | ||

| '''Class 1M''' || Similar to Class 1, but potentially hazardous if viewed with through magnifying optical aids such as magnifying lenses or binoculars. | | '''Class 1M''' || Similar to Class 1, but potentially hazardous if viewed with through magnifying optical aids such as magnifying lenses or binoculars. | ||

| − | + | || Avoid using magnifying devices to view the beam, and ensure the laser remains enclosed. Proper warning labels should be in place | |

|- | |- | ||

| '''Class 2''' || These are visible lasers (wavelengths 400–700 nm) with low power, typically under 1 mW. They are safe for short accidental exposure due to the blink reflex. Example: laser pointers. | | '''Class 2''' || These are visible lasers (wavelengths 400–700 nm) with low power, typically under 1 mW. They are safe for short accidental exposure due to the blink reflex. Example: laser pointers. | ||

| − | + | || Do not intentionally stare into the beam. Warn others about the laser, label the device clearly, and avoid directing it at people. | |

|- | |- | ||

| '''Class 2M''' || Like Class 2 but can be dangerous when viewed with optical instruments. | | '''Class 2M''' || Like Class 2 but can be dangerous when viewed with optical instruments. | ||

| − | + | || Avoid using magnifying devices to view the beam. Post warning signs and instruct users not to point the laser at people. | |

| + | |- | ||

| + | |rowspan="3"| '''Class 3''' ||colspan="2"| May be hazardous under direct and specular reflection viewing conditions but is normally not a diffuse reflection or fire hazard. There are two subclasses: | ||

| + | |- | ||

| + | |'''Class 3R''' lasers are more powerful (up to 5 mW) and can be hazardous if viewed directly for extended periods but are generally safe with brief exposure. Example: some laser pointers. || Direct exposure to the eyes should be avoided. Label the device properly, use warning signs, and limit access to trained users. Example: higher-power laser pointers. | ||

|- | |- | ||

| − | | | + | |'''Class 3B''' lasers can cause serious eye injury from direct or specular reflection exposure. Skin injury is less likely but possible. Example: industrial and research lasers. || Eye protection designed for the specific laser wavelength is essential. Never look directly at the beam or its reflections. Enclose the laser beam path where possible, post clear warning signs, and restrict access to trained personnel. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | '''Class 3B''' lasers can cause serious eye injury from direct or specular reflection exposure. Skin injury is less likely but possible. Example: industrial and research lasers. | ||

| − | |||

| − | |||

|- | |- | ||

| '''Class 4''' || These are the most hazardous lasers, capable of causing severe eye and skin injuries. They also pose a fire hazard. Direct, scattered, or reflected beams from these lasers are dangerous. Examples: cutting, welding, or medical lasers. | | '''Class 4''' || These are the most hazardous lasers, capable of causing severe eye and skin injuries. They also pose a fire hazard. Direct, scattered, or reflected beams from these lasers are dangerous. Examples: cutting, welding, or medical lasers. | ||

| − | + | || Use protective eyewear and clothing designed for the laser's wavelength and power. Enclose the laser and the beam as much as possible, employ interlock systems, post visible warning signs, and restrict access to a controlled area. Use laser safety curtains or shields to contain reflections. | |

|} | |} | ||

| Linha 750: | Linha 750: | ||

=Additional information= | =Additional information= | ||

==Preventive measures== | ==Preventive measures== | ||

| − | L2I is equipped with a variety of preventive measures to detect and prevent safety-related incidents. Make sure that you are thoroughly familiar with them, their location and operation. The table below details the location of each relevant item. See also | + | L2I is equipped with a variety of preventive measures to detect and prevent safety-related incidents. Make sure that you are thoroughly familiar with them, their location and operation. The table below details the location of each relevant item. See also the section [[http://www.mysolutions.tecnico.ulisboa.pt/wiki/index.php?title=Laser_Safety_Manual#L2I_floor_plan|L2I floor plan]] below for information about the location of each item. |

{| class="wikitable" | {| class="wikitable" | ||

| Linha 777: | Linha 777: | ||

Emergency door|| East wall, three-door exit || In the event of an emergency requiring users to exit the laboratory, the emergency door should be used. Although normally closed, this door opens to the outside by rotating the knob. | Emergency door|| East wall, three-door exit || In the event of an emergency requiring users to exit the laboratory, the emergency door should be used. Although normally closed, this door opens to the outside by rotating the knob. | ||

|} | |} | ||

| − | In case any of the items listed above isn’t working properly, you should notify the CE. | + | In case any of the items listed above isn’t working properly, you should notify the CE. |

==Electric panels== | ==Electric panels== | ||

| − | L2I is equipped with three electrical panels. The main one is Panel 3. | + | L2I is equipped with three electrical panels. The main one is Panel 3. The tables below detail the layout of each one, with the differential switches highlighted in blue. |

{| class="wikitable" | {| class="wikitable" | ||

| − | |+ | + | |+ '''Panel 1''' |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | | | + | | colspan=4 style="text-align: center;" | [[Ficheiro:L2i electrical board1.png|miniaturadaimagem|center]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | | | ||

|- | |- | ||

! Slot !! No. !! Amps !! Description | ! Slot !! No. !! Amps !! Description | ||

| Linha 818: | Linha 806: | ||

| 8 || 16 || | | 8 || 16 || | ||

|- | |- | ||

| − | | 9 || 40 || Differential switch for circuit breakers 1-8 | + | |bgcolor = "0088FF" | 9 || 40 || Differential switch for circuit breakers 1-8 |

|- | |- | ||

| 10 || 40 || | | 10 || 40 || | ||

| Linha 824: | Linha 812: | ||

| 11 || 40 || | | 11 || 40 || | ||

|- | |- | ||

| − | | 12 || 63 || Differential switch for circuit breakers 10-11 | + | |bgcolor = "0088FF" | 12 || 63 || Differential switch for circuit breakers 10-11 |

|- | |- | ||

| 13 || 10 || Lighting, north side of main hall | | 13 || 10 || Lighting, north side of main hall | ||

| Linha 830: | Linha 818: | ||

| 14 || 10 || Lighting, top floor | | 14 || 10 || Lighting, top floor | ||

|- | |- | ||

| − | | 15 || 25 || Differential switch for circuit breakers 13-14 | + | |bgcolor = "0088FF" | 15 || 25 || Differential switch for circuit breakers 13-14 |

|- | |- | ||

| rowspan=2 | Bottom | | rowspan=2 | Bottom | ||

| Linha 836: | Linha 824: | ||

|- | |- | ||

| 2 || 40 || Overhead circuit breaker (Amphos laser) | | 2 || 40 || Overhead circuit breaker (Amphos laser) | ||

| + | |} | ||

| + | |||

| + | |||

| + | {| class="wikitable" | ||

| + | |+ '''Panel 2''' | ||

| + | |- | ||

| + | | colspan=4 style="text-align: center;" | [[Ficheiro:L2i electrical board2.png|miniaturadaimagem|center]] | ||

| + | |- | ||

| + | ! Slot !! No. !! Amps !! Description | ||

| + | |- | ||

| + | | rowspan=7 | Top | ||

| + | | 1 || 40 || Differential switch for single phase sockets | ||

| + | |- | ||

| + | | 2 || 16 || Single-phase sockets (Fastlite) | ||

| + | |- | ||

| + | | 3 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 4 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 5 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 6 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 7 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | rowspan=3 | Middle | ||

| + | | 8 || 40 || Differential switch for three-phase sockets | ||

| + | |- | ||

| + | | 9 || 16 || Three-phase socket B | ||

| + | |- | ||

| + | | 10 || 40 || Three-phase socket C | ||

| + | |- | ||

| + | | Bottom || 11 || 63 || Global panel circuit breaker | ||

| + | |} | ||

| + | |||

| + | |||

| + | {| class="wikitable" | ||

| + | |+ '''Panel 3''' | ||

| + | |- | ||

| + | | colspan=4 style="text-align: center;" | [[Ficheiro:L2i electrical board3.png|miniaturadaimagem|center]] | ||

| + | |- | ||

| + | ! Slot !! No. !! Amps !! Description | ||

| + | |- | ||

| + | | rowspan=14 | Top | ||

| + | | 1 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 2 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 3 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 4 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 5 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 6 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 7 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | | 8 || 16 || Single-phase sockets | ||

| + | |- | ||

| + | |bgcolor = "0088FF" | 9 || 40 || Differential switch for circuit breakers 1-8 | ||

| + | |- | ||

| + | | 10 || || | ||

| + | |- | ||

| + | | 11 || || | ||

| + | |- | ||

| + | | 12 || 10 || | ||

| + | |- | ||

| + | | 13 || 10 || | ||

| + | |- | ||

| + | |bgcolor = "0088FF" | 14 || 63 || | ||

| + | |- | ||

| + | | rowspan=7 | Middle | ||

| + | | 15 || || Vacuum pump | ||

| + | |- | ||

| + | | 16 || || Overhead crane | ||

| + | |- | ||

| + | | 17 || || Three-phase socket | ||

| + | |- | ||

| + | |bgcolor = "0088FF" | 18 || 25 || Differential switch for circuit breakers 15-17 (?) | ||

| + | |- | ||

| + | | 19 || || Electrical panel 1 | ||

| + | |- | ||

| + | | 20 || || Air Treatment Unit | ||

| + | |- | ||

| + | |bgcolor = "0088FF" | 21 || || | ||

| + | |- | ||

| + | | Bottom || || || Global panel switch | ||

|} | |} | ||

| + | |||

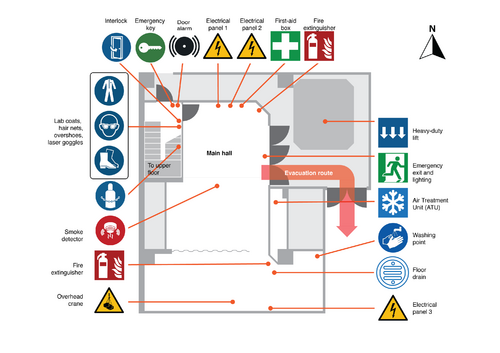

| + | ==L2I floor plan== | ||

| + | The figure below shows a schematic plan of L2I with items relevant to safety.<br /> | ||

| + | [[Ficheiro:L2I-Planta-legendas.png|500px|left|Flor plan of L2I.]] | ||

Edição atual desde as 17h42min de 20 de março de 2025

Latest revision: March 2025

Laboratory workers must be aware of its potential hazards, which can affect people, equipment, and the environment. In particular, safety is of paramount importance in a high-power laser laboratory. A safety manual is a foundational document that ensures the well-being of everyone working within the laboratory environment.

This document describes the rules, guidelines and protocols that must be followed by the users of the Laboratory for Intense Lasers in order to ensure safe working conditions. Before gaining access to working in the lab, users must be thoroughly familiar with these safety measures and acknowledge their understanding. There are a number of reasons why safety must be strictly implemented:

- by following safety rules, users acquire essential skills that are vital in a laboratory context, including the ability to identify and mitigate risks, correctly use personal protective equipment, handle hazardous materials and equipment safely, and respond effectively to emergency situations

- users are not only protecting themselves from potential hazards but also ensuring the integrity of their scientific work

- familiarity with safety protocols fosters a culture of responsibility and diligence, encouraging conscientious laboratory practices

- the knowledge and skills gained from being aware of and implementing safety measures contribute to the creation of a secure, productive, and harmonious work environment.

This manual is provided to all current and new users of L2I, including permanent or visiting members, researchers, students, trainees and technical staff. It describes the specific safety and health risks related to working at this laboratory and complements the information available in the general IST Laboratory Safety Manual, the IST NSHS Emergency Procedures and within the laboratory in the form of Standing Orders, first-aid instructions, fire and earthquake safety procedures or other local safety documentation.

New laboratory users or anyone planning to operate with lasers, equipment or machinery at L2I must obtain previous permission from the Laboratory Head. This implies that the user fully understands the inherent risks by completing the following three steps:

- reading thoroughly this manual

- completing the laser safety training

- signing the corresponding form

L2I users are responsible not only for their own safety but also for that of those around them. They must adhere to the active safety measures specific for each situation and ensure that other users also do the same. Any temporary or permanent change to a setup that introduces changes to the current safety protocol must be discussed in advance with the Laboratory Head of Chief Engineer/LSO.

This document is available in MediaWiki format and will be updated periodically.

Emergency instructions

Contacts

- European Emergency Number: 112

- IST Security Central: Ext. 2000 or tel. 218 418 000

- Emergency Assembly Point: in front of the Central Pavilion next to the flagpole (see image on the right)

Emergency procedures

The following summary of IST emergency instructions is intended for use in situations where an immediate danger poses a threat to an individual. All incidents/accidents should be reported to the CE as a mechanism to help preventing their reoccurrence.

Basic first aid guide

In the event of a personal accident:

- immediately stop any activities to take care of yourself or to assist others

- make sure that there are no active risks (e.g. the laser is left running) that could cause further accidents.

The table below details how to react to possible personal accidents at L2I, whether to oneself or to others:

| In case of | How to proceed |

|---|---|

| Light wound |

|

| Deep wound |

|

| Thermal or fire burning | Assess the severity of the burn:

For minor burns:

For severe burns:

|

| Electric shock |

|

L2I evacuation procedure

In the general event of a severe emergency requiring users to evacuate the laboratory, follow these actions:

- Dial 2000 and provide information about the problem.

- Abort all the experiments, shut down the electrical panel, and turn of any active machinery.

- Have everyone leave the room through the emergency exit.

- In the case of a small fire, and only if this procedure doesn’t increase the risks, use the appropriate portable extinguisher.

- Close (but don’t lock) the doors and leave the building, following the evacuation route.

Laboratory management structure

Management levels

The Laboratory for Intense Lasers (L2I) is dedicated to the study of laser-matter interaction at very high optical powers and is operated by the Group for Lasers and Plasmas of IPFN. The main research areas are laser science and technology, nonlinear optics, plasma physics, high harmonic generation, diode-pumped lasers and optical parametric amplification. L2I is a fundamental stepping-stone in the preparation of high-intensity experiments to be carried out at large-scale facilities, while also playing an important role in the advanced training of young researchers and technological development. Since 2013, L2I is a member of the National Roadmap of Strategic Research Infrastructures.

The Group for Lasers and Plasmas (GoLP), is part of the Instituto de Plasmas e Fusão Nuclear at IST. Their activity is focused on the study, both theoretical and experimental, of laser-plasma interactions and other phenomena associated with the interaction of high intensities with plasmas.

Instituto de Plasmas e Fusão Nuclear (IPFN, Institute for Plasmas and Nuclear Fusion) is a research unit of Instituto Superior Técnico (IST) with the status of Associated Laboratory granted by Fundação para a Ciência e a Tecnologia. IPFN ensures the Portuguese participation in EUROFusion, the European Consortium for the Development of Fusion Energy. Research at IPFN is organized into two thematic areas: controlled nuclear fusion and intense lasers and plasma technologies.

Management roles

The management roles at L2I meets the requirements necessary for a laboratory of its magnitude and consists of the following levels:

| Role | Management responsibilities related to safety |

|---|---|

| Laboratory Head (LH) |

|

| Chief Engineer / Laser Security Officer (CE/LSO) |

|

| Laser Users (LU) |

|

As of 2025 the management roles are as follows:

- Laboratory Head: Gonçalo Figueira, Hugo Pires (deputy)

- Chief Engineer: Jessica Diaz, Gonçalo Figueira (deputy)

User levels

At L2I system of controlled access through an ID card system (the same as for restricted access within IST) is in place. Entrance authorizations for L2I are issued by the CE upon request and depend on the context of the visit. The following categories of access are in place:

| Independent access |

|

| Accompanied access |

|

| Short term visitors |

|

Safety risks in the laboratory

General risk assessment

The list below describes the main hazards present in L2I. In this manual, particular attention is dedicated to laser risks (see next chapter), due to their specific characteristics.

| Chemical |

|

| Ergonomic |

|

| Physical |

|

| Safety |

|

Chemical risks

Compressed gases and high gas pressures

Several compressed gases are commonly used in the laboratory. They present a number of hazards for the laboratory user:

- Gas cylinders may contain gases that are flammable, toxic, corrosive, asphyxiants, or oxidizers.

- Unsecured cylinders can be easily knocked over, causing serious injury and damage.

- Impact can shear the valve from an uncapped cylinder, causing a catastrophic release of pressure leading to personal injury and extensive damage.

- Mechanical failure of the cylinder, cylinder valve, or regulator can result in rapid diffusion of the pressurized contents of the cylinder into the atmosphere.

It is fundamental that compressed gases are properly handled:

- Gas bottles must be clearly identified in a visible location.

- The laboratory location is incompatible with gases that can become dangerous through accumulation. These must be installed in a properly ventilated area outside.

- In the event that a dangerous gas must be temporarily present in the laboratory, adequate gas detectors must be installed to monitor for leaks.

- Ensure gas cylinders are stored upright and secured to prevent tipping over. See the section on ergonomic risks for the procedures related to gas bottle transportation.

When transporting gas cylinders:

- Always use a heavy duty hand truck equipped with a chain or belt for securing the cylinder.

- Make sure the protective cap is covering the cylinder valve.

- Never transport a cylinder while a regulator is attached.

- Always use caution when transporting cylinders – they are heavy and can easily tip over.

- Do not move compressed gas cylinders by carrying, rolling, sliding, or dragging them across the floor.

- Do not transport oxygen and combustible gases at the same time.

- Do not drop cylinders or permit them to strike anything violently.

Safe storage of compressed gas cylinders:

- Only the minimum essential number of cylinders must be inside the laboratory at any time

- Cylinders must be secured to the wall to prevent them from falling over.

- Cylinders should be stored away from heat, from areas where they might be subjected to mechanical damage or an electrical discharge.

- The protective cap should always be left on the cylinder when it is not in use. The cap keeps the main cylinder valve from being damaged or broken.

Safe operation of compressed gas cylinders:

- Make sure that the cylinder is secured.

- Attach the proper regulator to the cylinder. If the regulator does not fit, it may not be suitable for the gas you are using.

- Attach the appropriate hose connections to the flow control valve. Secure any tubing with clamps so that it will not whip around when pressure is turned on.

- To prevent a surge of pressure, turn the delivery pressure adjusting screw counterclockwise until it turns freely and then close the flow control valve.

- Slowly open the cylinder valve hand wheel until the cylinder pressure gauge reads the cylinder pressure.

- With the flow control valve closed, turn the delivery pressure screw clockwise until the delivery pressure gauge reads the desired pressure.

- Adjust the gas flow to the system by using the flow control valve or another flow control device between the regulator and the experiment.

- After an experiment is completed, turn the cylinder valve off first, and then allow gas to flow from the regulator. When both gauges read “zero”, remove the regulator and replace the protective cap on the cylinder head.

- When a cylinder is close to empty, notify your supervisor that a new cylinder should be ordered.

- When the cylinder is empty, mark it as “Empty”, and store it separate from full cylinders.

Hazards of specific gases: Inert gases (e.g. Helium, Argon, Nitrogen) – These gases can cause asphyxiation by displacing the air necessary to support life. Flammable Gases (e.g. Methane, Propane, Hydrogen, Acetylene) – These gases present serious fire and explosion hazards. Do not store near open flames or other sources of ignition. Flammable gases are easily ignited by heat, sparks, or flames, and may form explosive mixtures with air. Vapors from liquefied gas often are heavier than air and may spread along ground and travel to a source of ignition and result in a flashback fire.

| Gas | Cylinder color |

|---|---|

| Argon (Ar) | Dark green |

| Nitrogen (N2) | Black |

| Hydrogen (H2) | Red |

| Helium (He) | Brown |

Flammable liquids, including solvents and alcohol

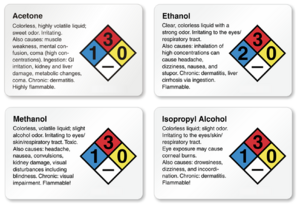

At the laboratory there are small amounts of liquid chemicals (see figure with safety labels), mainly used for cleaning optical or mechanical surfaces. The following instructions must be followed when storing and handling these liquids.

- All flammable liquids must be stored in approved containers with appropriate labels and stored in cabinets away from heat sources.

- When not in use, containers must remain tightly sealed to prevent the release of flammable vapours.

- When handling these liquids, always use gloves and work in areas with proper ventilation to disperse flammable vapours.

- Work away from all sources of ignition, such as laser beams, electrical equipment, and hot surfaces.

- Clean any spills immediately using appropriate cleaning materials.

- If working with large quantities, consider using a face shield and a respiratory mask to avoid inhaling harmful vapours.

Oil exhaustion from vacuum pumps

Oil-based vacuum pumps, such as rotary pumps, rely on the oil to lubricate, seal, and cool the internal components. As the pump is used, this oil is slowly exhausted to the atmosphere. To avoid contamination, ensure adherence to the following rules.

- Install oil mist filters or exhaust filters on vacuum pumps to capture oil vapours and prevent them from being released into the atmosphere. Regularly check and replace these filters as part of the pump maintenance schedule, as saturated filters can lose efficiency and allow oil to escape.

- Connect the pump exhaust to the ventilation tubing that directs the exhaust outside the work area.

- Always use the manufacturer-recommended oil. Different pumps require specific oil formulations to ensure optimal performance and minimal exhaust.

- Regularly check the oil level in the pump and ensure that it stays within the recommended range. Low oil levels can cause increased vaporization and inefficient operation, while overfilling can lead to excessive oil mist generation.

- Pump oil must be replaced regularly as per the pump manufacturer's guidelines. Old or contaminated oil can degrade, leading to increased exhaust emissions and poor pump performance.

Vapours and fumes from laser ablation

Laser ablation is a process where material is removed from a solid surface by irradiating it with a laser. This process can produce potentially hazardous vapours, fumes, and particulates, especially when working with metals, polymers, or other chemicals. For instance, metals can release toxic metallic fumes, polymers and plastics can release harmful organic compounds and coated surfaces or paints may release hazardous by-products, including volatile organic compounds and metal oxides. L2I is not designed to handle large amounts of vapours and fumes, and any such experiment must be preceded by a detailed study and risk assessment. Below are some directions to consider.

- Local exhaust ventilation or fume hoods should be in place to prevent the accumulation of hazardous vapours.

- Ensure that the extraction system is equipped with appropriate filters to capture particulate matter and chemical fumes.

- Maintain a well-ventilated work environment, with air circulation systems to prevent the build-up of toxic fumes in confined spaces.

- Wear appropriate respiratory protection in situations where there is a risk of inhaling toxic particles or vapours.

Ergonomic risks

Standing up for prolonged periods

Standing up for prolonged periods can pose significant risks to both physical health and overall comfort. Below are some recommended guidelines and practices to address this issue.

- Shift weight and change posture frequently; for instance, alternate between sitting and standing periods, if possible, to avoid constant strain on specific muscle groups.

- Take periodic rest breaks: for every hour of standing, aim for a 5-10 minute break

- Adjust the height of your workstation to prevent bending forward or raising arms unnecessarily.

- If possible, rotate tasks among users to ensure they aren't required to stand for extended periods without relief.

Back risk due to bending over large optical tables

Bending over large optical tables or other experimental setups can pose significant risks to the back, particularly over time, due to the awkward posture required to reach equipment or perform precision tasks. Prolonged or repetitive bending can strain muscles and joints, leading to discomfort, injury, and chronic pain. To mitigate these risks, here are some recommended guidelines and practices:

- Use elevated platforms or steps to bring you to the appropriate height, so that you do not have to bend over the table.

- Break up tasks that require bending by alternating with tasks that allow you to stand upright or sit.

- If objects or equipment on the optical table are heavy or awkward to handle, ask for help to avoid straining the back.

- Arrange the equipment and tools on the optical table so that frequently used items are within easy reach, reducing the need for excessive reaching and bending.

- Keep the workspace organized and free of clutter to minimize unnecessary movements that could lead to strain.

Moving or transporting heavy objects

Occasionally there may be a need to move, lift and/or transport heavy objects, such as laser system components, within the lab or to/from the exterior. The most important rule when handling heavy objects is to have someone helping you. The following safety guidelines will help you to avoid injuries, particularly to the back, shoulders, and legs.

- Evaluate the weight and size of the object before lifting. If the object is too heavy to lift comfortably, use mechanical aids or seek assistance from a co-worker.

- Ensure the path is clear of obstacles and plan the route before moving the object to avoid sudden movements or slips.

- If raising the load using your arms, bend at your knees – not your waist – and keep your back straight. Squat down and use your legs to lift the load, keeping the object close to your body (see figure).

- Avoid twisting your torso while lifting. Instead, turn your entire body by pivoting your feet to prevent back strain.

- Keep the load close to your centre of gravity (near your waist), which minimizes the strain on your back and upper body.

- Use dollies, carts, forklifts, or hand trucks whenever possible to move heavy objects. This reduces the physical strain on your body and minimizes the risk of injury.

- Ensure that any equipment used is appropriate for the load size and weight and that you know how to operate it safely.

- If the object is too heavy or awkward to lift alone, enlist help from one or more co-workers. Coordinate the lift by counting down and lifting at the same time.

- Ensure that all team members use proper lifting techniques and are on the same page regarding the movement plan.

- Wear proper gloves when handling rough equipment (e.g. wooden crates) to avoid skin abrasion.

Physical risks

Fire

See section Emergency procedures.

Laser exposure with potentially serious eye or skin injury

See section Laser safety.

High level noises

When working at L2I there are several sources producing continuous noise that can be bothersome after long hours of exposure. These include the Air Treatment Unit (ATU), chillers (air-cooled and water-cooled), fans and other noisy equipment. Continuous exposure to noise can lead to stress, fatigue, and other physical effects. Here are safety measures and practices for dealing with noisy environments:

- If you feel bothered by the noise level, consider wearing earplugs or earmuffs. Balance their use with the need of remaining aware to other risks in the laboratory, e.g. alarm sounds.

- Ensure that all noisy machinery is properly closed (e.g. the ATU doors)

- Take frequent rests and go outside the laboratory for a few minutes.

Cold temperature and low humidity

L2I is a Class 10,000 clean room with a temperature setting of around 20.0 degrees and humidity setting of around 40%. Working in this type of environment presents specific challenges that can affect both comfort and performance.

- When planning to work in the lab, choose clothing that provides good thermal insulation to prevent body heat loss.

- Schedule regular breaks in warmer environments to regulate your body temperature and avoid discomfort.

- Low humidity environments can lead to dehydration and dry skin. Drink water regularly to maintain hydration.

Compressed air

Compressed air is available in the laboratory for different uses. While it is a versatile tool, it poses several safety risks if not handled properly.

- Do not use compressed air to clean skin, clothes, or surfaces where people may come into contact with the air. The high-pressure air can penetrate the skin, causing serious injuries, and dislodge particles that can damage eyes or be inhaled.

- Never point a compressed air nozzle at yourself or others, as this can result in serious injuries. Even low-pressure air can be dangerous when directed at a person's body.

- Always wear safety goggles or a face shield when using compressed air to prevent debris from being blown into your eyes.

- Keep compressed air at a safe working pressure for the task at hand.

- When using air tools, make sure they are properly secured to avoid them becoming projectiles due to the force of compressed air.

- The compressed air cylinders should be stored properly and kept them away from heat sources or sparks.

Falling from heights, including ladders and elevated work areas

Falling from heights, ladders, or elevated work areas, is a serious safety hazard that must not be dismissed. At L2I the need to work at a height may arise e.g. from climbing onto tables or others heavy furniture to assemble setups, cabling, curtains, etc. Electrical maintenance should be performed by specialised technicians only.

- Ensure that ladders are in good condition, appropriately rated for the weight load, and placed on stable ground.

- Maintain 3 points of contact (two hands and one foot, or two feet and one hand) when climbing.

- Always face the ladder when climbing up or down and use both hands for stability.

- Do not stand on the top rungs or overreach; reposition the ladder if needed.

- Plan the task to minimize time spent working at heights. Where possible, perform tasks on the ground or use equipment to bring the work area to a safer level.

- Keep tools and materials secured to prevent them from falling and causing injury to others below.

Safety risks

Hard surfaces

Virtually all the work surfaces at L2I are hard, which can lead to head or facial injuries from accidental contact or impact.

- Mark overhead obstacles and protruding objects at head height with bright (e.g. yellow or black/yellow tape) or warning signs to ensure they are easily noticeable.

- Use padding or cushioning materials to cover hard surfaces that could pose a risk of head impact to soften any accidental contact. For instance, bubble wrap or impact foam can be used for this (see figure).

- In a situation of potential head injury, e.g. working under an optical table, wear a hard hat.

- Where possible, relocate or modify hard surfaces at head level to reduce the risk of injury. For example, adjust shelving, overhead storage, or equipment to minimize contact with head-level surfaces.

- Ensure that walkways and workstations are designed to avoid head-level hazards. Clear paths of low-hanging obstacles and ensure enough clearance for users to move safely.

- Always use adequate lighting to ensure that you can see obstacles clearly.

Electrical hazards, including high voltage

At L2I there is a large amount of electrical equipment, including high voltage equipment. Although electrical circuits are mostly confined to these devices, on some occasions users may have to install electrical circuits in the setups. The use of high voltage outside professional equipment should only be done under the assistance of an electrical technician. To address electrical hazards, it's crucial to follow comprehensive safety guidelines.

- Identify high voltage areas: clearly mark and label areas where high-voltage (>600 V) equipment is present. Use warning signs such as "Danger – High Voltage."

- Insulation and barriers: High-voltage cables and equipment should be properly insulated and enclosed to prevent accidental contact. Ensure barriers or physical guards are in place where necessary.

- Avoid placing electrical cables in high-traffic areas to reduce the risk of tripping and damage. If unavoidable, use rubber cable covers (see figure) to protect both cables and people.

- Neither cables nor electrical equipment should be laid in areas prone to water accumulation (e.g., near the ATU or the water basin) to avoid electrical shock hazards.

- Whenever possible, run cables along walls or optical tables using cable trays or conduits.

- Keep cables away from sharp objects or edges that could cause damage or fraying of the insulation.

- Check cords for damage or wear, especially at the plugs and along the insulation before each use. Any cables compromised with cuts or damage should be disconnected and replaced immediately.

- Avoid plugging too many high-wattage devices into a single outlet. Use power strips with surge protectors to distribute electrical load evenly, but even those should not be overloaded. Never use multi-plug adapters instead of power strips.

- Do not overload extension cords or daisy-chain them together. Overloaded cords can lead to overheating and fire hazards.

- All electrical equipment and systems should be properly grounded to prevent the risk of electric shock.

- Label all electric cords with a description of the device they are connected to. This saves time when solving problems.

- Never handle electrical equipment with wet hands.

Confined or blocked spaces

Confined or blocked spaces, such as when working in a tight space between a large optical table and a wall or under an optical table, pose significant risks. A confined space is typically an area not designed for continuous occupancy and with limited access. Working in such a space should be considered only as an exceptional circumstance. Experimental setups that require a user to stay in a confined space must be absolutely avoided. A blocked space can also result from an improperly placed large object obstructing the passage, namely preventing a user from reaching the emergency exit in a swift manner. This type of action is only acceptable during exceptional maintenance and for periods as short as possible.

- Remove obstacles that could block the passage or access to any point in the laboratory. Ensure a clear path for entry and exit to prevent users from being trapped or hindered in emergencies.

- Plan tasks efficiently to minimize the time spent in tight or blocked spaces.

- If blockages are unavoidable due to equipment or maintenance, schedule tasks to remove or rearrange objects regularly to keep the space safe and accessible.

- Avoid working in confined or blocked spaces when alone in the laboratory.

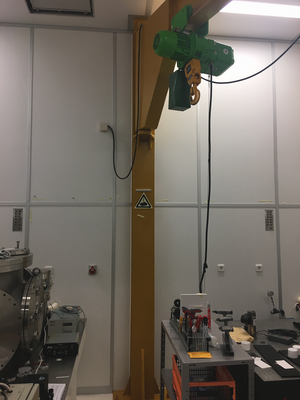

Lifting heavy objects using the crane

L2I is equipped with a crane capable of lifting heavy objects up to 2000 kg. If you don’t know how to operate the crane, ask for assistance. Do not try to operate it yourself as this can pose significant risks, both personal (e.g. being trapped under a heavy load) and to the equipment.

- You should preferably use the crane when someone else is in the laboratory.

- Assess the load: Determine the weight and dimensions of the object to be lifted. Ensure that the crane’s lifting capacity, as well as the rigging equipment (cables, shackles, etc), are suitable for the load, and that all rigging equipment (slings, shackles, etc.)

- Review the lift plan with everyone involved. This includes determining the safest path of travel and identifying potential obstacles.

- Ensure the load is properly balanced and secured before lifting. Use appropriate rigging to avoid slippage, tilting, or shifting during the lift.

- Wear a hard helmet and safety gloves. Never stand under the load, in any circumstances.

- The L2I crane has two speeds. Always lift and lower the load using low speed and steadily to avoid sudden movements that could cause the load to swing or shift. The fast speed should only be used when the lead is clear from surrounding objects and persons.

- Displace the load slowly and using the auxiliary chain. Do not pull the load directly.

- The crane has a specific maintenance plan. Warn the CE in case anything seems out of order.

Tripping and slipping

This risk is related to confined or blocked spaces, but also includes smaller obstacles that, while not preventing the passage, may lead to the user tripping and falling. For obvious reasons, this may lead to significant physical injury. Leaving objects lying on pathways is a severe violation of workplace safety that must be avoided. This includes e.g. backpacks, bags, tools, steps, boxes, computers and other equipment, cables and anything that prevents the user from walking safely.

- Ensure that all paths are free of clutter such as personal items, equipment, boxes, or other objects that could cause tripping.

- Avoid leaving loose objects on the floor, such as tools, materials, or waste.

- Use cable management systems, such as cable covers to keep cords organized and off the floor.

- In pathways, ensure that any cords crossing the floor are properly secured with cable covers to prevent tripping hazards. Cables should never be left loose or stretched across high-traffic areas without proper protection.

- If cords cannot be removed from a walkway, they should be raised above floor level or rerouted along walls or ceilings to eliminate the tripping risk.

- Any spills should be cleaned up immediately.

- The floor at L2I is marked with a fluorescent tape on the floor to guide you to the exit in the event of a power failure.

Water leaks and floods

Although L2I is equipped with a water drain, next to the basin, unexpected floods can happen as a result of water leaks, defective tubing or machinery malfunction (e.g. the ATU). A flood in a laboratory can quickly become a major source of damage to equipment unless a set of rules is strictly adhered to.

- Water leaks and floods in workplaces, homes, or industrial settings can lead to significant damage and safety hazards, including electrical risks, structural damage, mold growth, and slip-and-fall injuries. Addressing these risks requires a combination of preventive measures and emergency response procedures. Below are essential guidelines to handle and prevent water leaks and floods:

- In case you identify any water-related issue, e.g. a dripping tube, pools of water o the floor, accumulation of droplets, signs of corrosion etc that could lead to larger water leaks, immediately notify the CE.

- Keep the water drain unobstructed and periodically check its cleanliness.

- Avoid placing electrical objects on the floor, instead placing them on the tables, overhead shelves or elevated on solid blocks.

In the event of a significant water leak or flood:

- Immediately notify the Security Central and ask them to turn off the water supply (located outside the laboratory).

- Turn off electrical power to the affected areas to prevent electrocution or fire hazards, especially if water comes into contact with electrical outlets or appliances.

- Avoid entering flooded areas where electrical outlets, devices, or wires are submerged until the power has been safely disconnected.

- Open the laboratory doors to avoid rising water levels.

- Evaluate the extent of the possible damage: unless you think that you can manage the flood until help arrives, do not stay in the laboratory.

- After the water is removed, ensure that affected areas are thoroughly dried out.

Other rules and work practices

Cleanroom rules

The entire laboratory space is a certified Class 10,000 clean room. Specific cleanliness measures are in place to ensure that this status is met consistently, and the laboratory is maintained free of dust and contaminants. In particular, users must actively ensure that the rules below are followed at all times.

- Before entering the main laboratory hall or the upper floor, users must wear a lab coat, shoe covers and a hair net. For work involving the handling of delicate optical surfaces, latex gloves must be worn. These items are available at the entrance to the main hall.

- Personal items such as coats or other clothing, bags, and backpacks must be left outside the main hall. A small table with decks and a rail with coat hangers are available.

- Items made of particulate-generating materials are non-cleanroom compatible and must be left outside the lab. This includes cardboard or wood boxes, uncleaned or corroded metal, oily or dusty surfaces, and fabrics such as wool.

- The main door should be kept open for only the minimum time required. A loud beeping sound is heard while the door is open to remind users of this.

- Inside the clean room, avoid movements or actions that could create turbulence in the air, such as fast motions or making wide movements. Inspect large surfaces for dirt before moving them and clean them if needed.

- Ensure that the working surfaces are left clean and tidy after completing your work. Dispose of waste materials in the designated containers.

- Do not obstruct the clean room filtration systems.

- Notify the CE in case any abnormal accumulation of dust is detected.

Workplace rules

- Return of equipment and tools: at the end of each lab session, ensure that all common equipment, instruments, and tools are returned to their designated locations. This is essential to prevent delays and confusion for other users."

- Working area clean-up: always clean your workstation after use and properly dispose of all waste materials in the appropriate bins.

- Taking equipment outside the lab: removing equipment, tools, or components from the lab without explicit written authorization from the Lab Head (LH) or Chief Engineer (CE) is strictly prohibited. Any requests to take items out of the lab must be submitted in writing, detailing the specific items, their destination, and the expected duration of removal.

- Personal Protective Equipment: Ensure that all required PPE is worn during lab activities and that PPE is returned to its designated storage location after use.

- Reporting incidents: report any damaged equipment, spills, or incidents immediately to the CE or LH to ensure prompt resolution and maintain a safe working environment.

- Respect for shared spaces: be mindful of shared spaces and resources. Avoid monopolizing equipment for extended periods and communicate with others to ensure smooth lab operations.

Working hours

As a general rule, due to the location, restricted access and general risks present in the laboratory, working accompanied is strongly recommended, in particular when using the high-power laser systems. If absolutely required, a user may stay alone in the lab for a limited time, in which case the following protocol must be followed:

- the user formally notifies a colleague, the CE or the LH of their intentions and makes sure that the message was received.

- after finishing the work session, the user again contacts the said person to confirm that he/she has left the lab; failure to do so may trigger an emergency warning due to absence of contact.

Plans for foreseeable and repeated periods of working alone must be discussed with the LH or the CE.

Laser safety

Adequate laser safety measures are essential to protect individuals, equipment, and the environment from potential hazards associated with laser use. High-power lasers can cause severe injuries, including eye and skin damage, as well as fire hazards and material degradation. Implementing safety protocols, such as using appropriate protective eyewear, controlling beam exposure, and enforcing access restrictions, minimizes risks and ensures a safe working environment. Additionally, adherence to safety regulations and best practices not only prevents accidents but also promotes responsible use of laser technology in research, industry, and medical applications. A well-informed and safety-conscious approach is crucial to maintaining both operational efficiency and the well-being of all personnel.

Training

L2I hosts several laser systems with a wide range of parameters. Up to date information is available on the internal web pages and in the form of Standing Orders before entering the main hall. Laser safety training is mandatory for all prospective users. This consists of individual study and accompanied access to the L2I lasers.

Individual study is done through reading materials (including, but not limited to, the present manual) and videos, and aims at acquiring a thorough knowledge of the following concepts:

- Classification of lasers and laser systems: wavelengths, CW/pulsed, energy, power, exposure

- General laser safety principles: personal protective equipment, control measures

- Effects of laser radiation on the human body and emergency procedures

Accompanied access consists of a predetermined number of initial sessions in the laboratory during which the used acquires practical training in the safety measures and operation of the laser systems, supervised by a registered user. The emission of independent access status depends on the positive evaluation concerning the understanding and adherence to safety measures.

Guest visits

Guest visits to the lab may occur with short notice and can include colleagues, visitors, students, journalists, or other external parties. To accommodate these visits smoothly and safely, the following guidelines must be followed:

- The visit must be scheduled as soon as possible with both the current lab users and the CE to avoid disruptions to ongoing experiments and ensure proper preparation. The corresponding slot must be reserved in the team's calendar.

- During the entire duration of the visit, all laser systems must be either powered down or securely blocked to prevent accidental exposure. No active laser beams are allowed.

- Guests are required to wear cleanroom PPE. Prior to the visit, they should be given a brief orientation to ensure they understand and comply with cleanroom protocols.

- Guests must be supervised at all times during their visit by lab personnel to ensure compliance with safety standards and prevent unauthorized handling of equipment.

Classification of lasers and laser systems

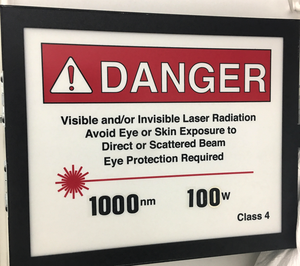

Lasers are classified into four main safety classes based on their potential risk to human eyes and skin, as detailed in the tables below. The first table provides a quick summary of laser classes and the second one details the specific considerations within each class.

| Laser class | Risk level | Precautions |

|---|---|---|

| Class 1 | Minimal | No special precautions |

| Class 2 | Low | Avoid staring into the beam |

| Class 3 | Moderate | Use protective eyewear and barriers |

| Class 4 | High | Full enclosure, protective eyewear, no direct exposure |

| Laser class | Description | Safety measures |

|---|---|---|

| Class 1 | These lasers are considered safe under all conditions of normal use. The output power is low enough that it poses no hazard, even with prolonged exposure. Example: laser printers. | No specific safety precautions are required, but it is important to ensure the laser is used as intended and remains properly enclosed. |

| Class 1M | Similar to Class 1, but potentially hazardous if viewed with through magnifying optical aids such as magnifying lenses or binoculars. | Avoid using magnifying devices to view the beam, and ensure the laser remains enclosed. Proper warning labels should be in place |

| Class 2 | These are visible lasers (wavelengths 400–700 nm) with low power, typically under 1 mW. They are safe for short accidental exposure due to the blink reflex. Example: laser pointers. | Do not intentionally stare into the beam. Warn others about the laser, label the device clearly, and avoid directing it at people. |

| Class 2M | Like Class 2 but can be dangerous when viewed with optical instruments. | Avoid using magnifying devices to view the beam. Post warning signs and instruct users not to point the laser at people. |

| Class 3 | May be hazardous under direct and specular reflection viewing conditions but is normally not a diffuse reflection or fire hazard. There are two subclasses: | |

| Class 3R lasers are more powerful (up to 5 mW) and can be hazardous if viewed directly for extended periods but are generally safe with brief exposure. Example: some laser pointers. | Direct exposure to the eyes should be avoided. Label the device properly, use warning signs, and limit access to trained users. Example: higher-power laser pointers. | |

| Class 3B lasers can cause serious eye injury from direct or specular reflection exposure. Skin injury is less likely but possible. Example: industrial and research lasers. | Eye protection designed for the specific laser wavelength is essential. Never look directly at the beam or its reflections. Enclose the laser beam path where possible, post clear warning signs, and restrict access to trained personnel. | |

| Class 4 | These are the most hazardous lasers, capable of causing severe eye and skin injuries. They also pose a fire hazard. Direct, scattered, or reflected beams from these lasers are dangerous. Examples: cutting, welding, or medical lasers. | Use protective eyewear and clothing designed for the laser's wavelength and power. Enclose the laser and the beam as much as possible, employ interlock systems, post visible warning signs, and restrict access to a controlled area. Use laser safety curtains or shields to contain reflections. |

Laser safety: main parameters

Laser hazards vs. wavelength range

Concerning ocular hazards, the potential damage caused by laser radiation to the eyes is strongly dependent on its wavelength region:

Ultraviolet light (<400 nm) tends to be absorbed in the eye lens (<400 nm) and in the cornea (<300 nm), where it can produce injuries at relatively low powers due to photochemical damage.

Visible light (400–700 nm) is mainly absorbed by the retina, where it can cause both photochemical and thermal damage at high intensities or prolonged exposure. Blue light (400–500 nm) is particularly hazardous as it can lead to photochemical damage to the retinal cells, even at lower power levels.

Infrared light (>700 nm) mainly causes thermal damage to the retina at near-infrared wavelengths and to more frontal parts of the eye at longer wavelengths.

The table below summarizes the various medical conditions caused by lasers at different wavelengths, not including injuries due to pulsed laser radiation.

| Wavelength range | Effects |

|---|---|

| 180–315 nm (UV-B, UV-C) | Photokeratitis (inflammation of the cornea, equivalent to sunburn) |

| 315–400 nm (UV-A) | Photochemical cataract (clouding of the eye lens) |

| 400–780 nm (visible) | Photochemical damage to the retina, retinal burn |

| 780–1400 nm (near-IR) | Cataract, retinal burn |

| 1.4–3.0 µm (IR) | Aqueous flare (protein in the aqueous humour), cataract, corneal burn |

| 3.0 μm–1 mm | Corneal burn |

Note that the blink reflex is only triggered for light in the visible region, as the eye cannot detect UV or IR light. This makes these wavelength regions particularly dangerous, as a significant exposure may happen without the user being aware. Concerning laser-induced skin injuries, these depend on the power and type of laser, as listed below.

| Type | Description |

|---|---|

| Thermal burns | Lasers operating in the visible and IR regions can cause thermal burns due to the absorption of laser energy by the skin, which is then converted to heat. This can result in mild burns (redness, swelling) or severe burns (blisters, tissue damage), especially when working with high-power lasers (e.g., Class 4 lasers). |

| Photochemical damage | UV lasers (<400 nm) can cause photochemical reactions in the skin, leading to erythema (similar to sunburn) or, over time, increasing the risk of skin cancer due to DNA damage. Long-term exposure to UV lasers can be particularly dangerous. |

| Mechanical damage | High-energy pulsed lasers can cause mechanical damage by creating rapid pressure changes in tissues. This can result in localized skin trauma or tissue fragmentation (bruising, tissue tearing, or open wounds) |

Other laser parameters

From the viewpoint of laser safety, apart from wavelength lasers can be described based on additional key parameters. The table below lists the main factors that directly influence the potential hazards a laser presents and the safety measures that should be applied.

| CW lasers | Continuous Wave (CW) lasers emit a constant beam of light over time, meaning their power output is steady. The risk to eyes and skin depends on the total power output and the duration of exposure. Prolonged exposure to CW lasers, especially at high powers, increases the risk of thermal damage.

For CW lasers, exposure limits are set based on the power and duration of the beam. Eye protection and beam control are crucial for high-power CW lasers. |

| Pulsed lasers | Pulsed lasers emit light in short bursts or pulses, with very high peak powers during each pulse, even if the average power over time is low. Pulsed lasers can deliver a large amount of energy in a very short period, making them particularly hazardous. Pulses are often used in applications like material ablation and medical procedures.

For pulsed lasers, the peak power and pulse duration are critical. Even short exposure to a single pulse can cause severe damage to eyes or skin, depending on the laser's energy and repetition rate. Special care must be taken to limit exposure. |

| Energy | This parameter is typically measured in joules (J) and refers to the amount of energy delivered per pulse for pulsed lasers. The higher the energy, the greater the potential for damage, especially in pulsed lasers where a single pulse can cause significant harm.

The energy per pulse is a critical factor in determining the level of eye protection needed. Pulsed lasers with high energy per pulse are particularly dangerous, as they can cause immediate damage to tissues, especially the retina. |

| Power | This parameter is usually measured in watts (W) and describes the rate at which energy is delivered. For CW lasers, power is the primary safety concern. Higher power means more energy is delivered over time, increasing the risk of burns and thermal injuries.

Higher-power lasers, both CW and pulsed, require strict control measures, including the use of protective eyewear, proper beam enclosures, and controlled access areas to prevent accidental exposure. The power output must be factored into determining maximum permissible exposure (MPE) limits. |

| Beam size | Beam size refers to the diameter of the laser beam at the point of emission or at the target area. A smaller beam size concentrates the laser energy over a smaller surface area, potentially increasing the intensity of the beam and its risk of causing localized damage to tissues.

A smaller, highly focused beam poses a greater hazard to localized areas of the skin or eyes. Appropriate shielding and precision in alignment are essential to prevent accidental exposure. |

| Beam divergence | Beam divergence is the degree to which a laser beam spreads as it propagates away from its source, usually measured in milliradians (mrad). Lasers with low divergence remain focused over long distances, maintaining their hazardous potential far from the source, whereas lasers with high divergence spread out more quickly, reducing their intensity over distance.

Lasers with low divergence pose a greater risk to distant objects, making it critical to establish clear boundaries and use warning signs for long-range laser applications. Diverging beams may still be hazardous at close range, so personal protective equipment and beam barriers are essential regardless of the divergence rate. |

| Exposure duration | Exposure refers to the duration of time a person or object is subjected to the laser beam. Even low-power lasers can be harmful with prolonged exposure, particularly to the eyes. Shorter exposure times reduce the chance of injury, while longer exposure increases the risk, especially with CW lasers.

Exposure duration is especially important in settings where the laser beam is not properly controlled. The risk of eye injury increases dramatically with longer exposure to even moderate-power lasers. Safety measures such as automatic shut-off systems, beam shutters, and the enforcement of exposure time limits are necessary. |

| Pulse duration | Pulse duration (for pulsed lasers) is the length of time each laser pulse lasts, typically measured in femtoseconds (fs), picoseconds (ps), or nanoseconds (ns). Shorter pulse durations can lead to higher peak intensities, which increase the risk of damage even if the total energy or average power is low.

Ultrafast lasers (with very short pulse durations) can deliver extremely high-intensity pulses that may cause immediate damage. Extra caution, such as using safety interlocks and barriers, is required when working with such lasers. |

| Repetition rate | Repetition rate (for pulsed lasers) is the frequency at which pulses are emitted, measured in Hertz (Hz). High-repetition-rate pulsed lasers fire pulses rapidly, meaning that even if the energy per pulse is moderate, the cumulative exposure can be substantial. A higher repetition rate increases the likelihood of injury over time.

A high repetition rate raises the risk of cumulative damage, especially to the eyes, as the frequency of pulses increases the likelihood of repeated exposure. Controlling exposure through beam shutters or limiting access during operation is crucial. The repetition rate is also important when determining appropriate protective eyewear, as it affects the total dose of laser radiation over a given period. |

Laser safety procedures and principles

This section outlines the immediate steps to take in the event of an injury caused by laser exposure to the eyes, skin, or other body parts whether to yourself or to others. In the event of any laser injury, speed is critical. In particular, prompt medical attention is essential for laser-induced eye injuries. Early treatment can help prevent long-term damage. Ensure that you read these instructions thoroughly to prevent any time loss during an emergency.

Emergency procedures

In the event of any accident involving laser exposure:

| Stop operation | Immediately stop the laser system and turn off the laser source to prevent further exposure |

| Isolate the area | Ensure the affected area is safe by controlling the laser beam and preventing anyone else from entering the hazard zone. |

| Evaluate the situation | Quickly assess the injury, focusing on the type of laser (CW or pulsed), wavelength, power, and duration of exposure. This information will be useful for medical personnel. |

Type of laser exposure

| Eye exposure | Symptoms: Flashing lights, loss of vision, blind spots, difficulty focusing, pain in the eyes, or the feeling of something "in the eye".

|

| Skin exposure | Symptoms: Redness, swelling, burns, blistering, or pain on the affected skin area. Laser-induced burns can range from minor to severe, depending on the laser class and exposure.

|

| Inhalation of fumes or debris (from laser processing) |

Symptoms: Respiratory irritation, coughing, shortness of breath, dizziness, or nausea due to inhalation of harmful fumes from materials vaporized by the laser (e.g., plastics, metals).

|

Report the incident to the LSO, detailing the laser type, incident location, nature of the injury, and actions taken. Ensure proper documentation for legal and medical purposes.

Personal protection and control measures

Working with high-power lasers (Class 3B and Class 4) presents significant hazards, including severe eye and skin injuries, as well as the potential for indirect hazards such as fires. Therefore, it is critical to implement stringent personal protective equipment (PPE) and control measures to minimize the risks of accidental exposure.

Personal Protective Equipment (PPE)

| Laser safety eyewear |

|

| Protective clothing |

|

Control measures

| Basic safety measures | In a laser laboratory safety is fundamental. Excuses such as “being in a hurry”, “not having the proper components” or “just doing a quick test” are no justification for overlooking the basic rules below!

|

| Beam enclosures, barriers and beam dumps | Physical barriers help contain the laser beam within a designated area and protect personnel from accidental exposure.

|

| Warning signs and labels |

Signage is available to inform personnel and visitors about the presence of laser hazards.

|

Daily operation and maintenance

This chapter lists the basic instructions for preparing, conducting and completing experiments at L2I.

Before an experiment

All proposed experiments, whether by internal or external users, must undergo a preliminary review by the CE and LH to assess the feasibility, safety, and availability of resources. The procedure for proposing an experiment starts with filling the Proposal Template (TBD) The experiment proposal must include:

- objectives, required equipment, estimated length and anticipated results

- list of participants, including their approval status; new users will have to undergo laser safety training to obtain approval

- detailed risk assessment of potential hazards

- laser sources to be used and laser safety plan (e.g., proper eyewear, beam enclosures, beam dumps)

- main equipment list (optical components, instruments, detectors, etc). Verify their availability and proper functioning.

- proposed experimental configuration, including the layout of the laser, optical components, and targets, must be reviewed and approved by the **Laser Safety Officer (LSO)** before commencing work.

During an experiment

Most of this Safety Manual already deals with the proper attitude towards safety in the course of an experiment. The rules below complement all the previous information.

- ensure that only authorized personnel are allowed in the main laser hall.

- whenever a laser is used, ensure that the correct status is shown on the laser safety display at the entrance.

- double-check with anyone entering the lab that they are wearing the correct type of laser PPE.

- allocate sufficient time for experimental setup, including preliminary checks, beam alignment, and safety verifications.

- ensure enough time is available to dismantle the setup once the experiment is complete.

After the experiment

- evaluate if all safety measures worked as expected and identify any potential improvements for future experiments.

- ensure all equipment is returned to its designated locations and that any damaged or faulty equipment is reported to the CE.

- ensure proper disposal of all materials used during the experiment.

- clean up the workstation and ensure no hazardous materials, equipment, or tools are left behind that could pose a risk to the next user.

The maintenance operations are from the responsibility of the chief engineer. All the urgent maintenance interventions should be booked as soon as possible, stopping the investigation work, if necessary – safety measures are more important for users than scientific deadlines.

Equipment requiring additional training

There are several components at L2I that require previous training to be properly used, some of which have already been described (e.g. lasers sources, crane). If you are unsure about how to use any of the devices below, contact first the CE or anyone familiar with their use.

- Air Treatment Unit

- vacuum pumps and vacuum control system

- vacuum chambers

- lab crane (see Section)

- heavy-duty lift (outside the lab room)

- gas cylinders (see Section 4.2)

- laser diode drivers

- Pockels cell drivers and other high voltage source

- data acquisition equipment

Maintenance

Regular maintenance, both scheduled and when needed, is the responsibility of the CE. Any malfunction or request for extraordinary maintenance must be communicated immediately to the CE.

Additional information

Preventive measures

L2I is equipped with a variety of preventive measures to detect and prevent safety-related incidents. Make sure that you are thoroughly familiar with them, their location and operation. The table below details the location of each relevant item. See also the section [floor plan] below for information about the location of each item.

Interlock system || Changing room || Panel displaying the status (on/off) of the Amphos laser. Emergency door|| East wall, three-door exit || In the event of an emergency requiring users to exit the laboratory, the emergency door should be used. Although normally closed, this door opens to the outside by rotating the knob.| Item | Location | Description |

|---|---|---|

| Electrical panel 1 Electrical panel 2 |

North wall | General electrical panels, including labelled circuit breakers. |

| Electrical panel 3 | South wall | Electrical panel for the interaction area, including labelled circuit breakers. |

| Automatic smoke detector | Ceiling | Automated smoke detector connected to a central alarm system. |

| Portable extinguishers | North wall and next to the basin | CO2 fire extinguishers, suitable for electrical fires and flammable liquids. Make sure to ventilate the area after using, as CO2 displaces oxygen. |

| First aid kit | North wall | Basic first aid kit is available for minor injuries such as cuts or abrasions. |

| Individual protection equipment | Changing room | Cleanroom PPE includes lab coats, overshoes, hair nets and latex gloves. Other PPE equipment includes hard hats, heavy duty gloves and face masks. |

| Laser goggles | Changing room | Specific laser safety goggles are available, covering all the wavelengths used in the laboratory. Make sure to select the right one. |

| Emergency lights and fluorescent tape | Ceiling (lights) and walking paths (tape) | In the event of a power cut, the emergency lights will be automatically turned on, allowing users to leave the laboratory. An auxiliary fluorescent tape path is marked on the floor. |

| Emergency key | To the right of the main door, inside the laboratory | In the event of a power failure, the main door electric shutter may not work properly. In this case, the emergency key can be used to open the door. |

In case any of the items listed above isn’t working properly, you should notify the CE.

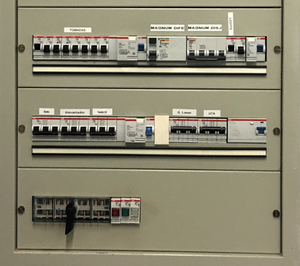

Electric panels

L2I is equipped with three electrical panels. The main one is Panel 3. The tables below detail the layout of each one, with the differential switches highlighted in blue.

| Slot | No. | Amps | Description |

|---|---|---|---|

| Middle | 1 | 16 | |

| 2 | 16 | Top floor electrical sockets | |

| 3 | 16 | Top floor electrical sockets | |

| 4 | 16 | ||

| 5 | 16 | ||

| 6 | 16 | ||

| 7 | 16 | ||

| 8 | 16 | ||

| 9 | 40 | Differential switch for circuit breakers 1-8 | |

| 10 | 40 | ||

| 11 | 40 | ||

| 12 | 63 | Differential switch for circuit breakers 10-11 | |

| 13 | 10 | Lighting, north side of main hall | |

| 14 | 10 | Lighting, top floor | |

| 15 | 25 | Differential switch for circuit breakers 13-14 | |

| Bottom | 1 | 100 | Global L2I circuit breaker |

| 2 | 40 | Overhead circuit breaker (Amphos laser) | |

| Slot | No. | Amps | Description |

|---|---|---|---|

| Top | 1 | 40 | Differential switch for single phase sockets |

| 2 | 16 | Single-phase sockets (Fastlite) | |

| 3 | 16 | Single-phase sockets | |

| 4 | 16 | Single-phase sockets | |

| 5 | 16 | Single-phase sockets | |

| 6 | 16 | Single-phase sockets | |

| 7 | 16 | Single-phase sockets | |

| Middle | 8 | 40 | Differential switch for three-phase sockets |

| 9 | 16 | Three-phase socket B | |

| 10 | 40 | Three-phase socket C | |

| Bottom | 11 | 63 | Global panel circuit breaker |

| Slot | No. | Amps | Description |

|---|---|---|---|

| Top | 1 | 16 | Single-phase sockets |

| 2 | 16 | Single-phase sockets | |

| 3 | 16 | Single-phase sockets | |

| 4 | 16 | Single-phase sockets | |

| 5 | 16 | Single-phase sockets | |

| 6 | 16 | Single-phase sockets | |

| 7 | 16 | Single-phase sockets | |

| 8 | 16 | Single-phase sockets | |

| 9 | 40 | Differential switch for circuit breakers 1-8 | |

| 10 | |||

| 11 | |||

| 12 | 10 | ||

| 13 | 10 | ||

| 14 | 63 | ||

| Middle | 15 | Vacuum pump | |

| 16 | Overhead crane | ||

| 17 | Three-phase socket | ||

| 18 | 25 | Differential switch for circuit breakers 15-17 (?) | |

| 19 | Electrical panel 1 | ||

| 20 | Air Treatment Unit | ||

| 21 | |||

| Bottom | Global panel switch | ||

L2I floor plan

The figure below shows a schematic plan of L2I with items relevant to safety.